-

Accesorios de tubería de titanio

-

Tubo soldado con autógena titanio

-

Brida de tubo de titanio

-

Tubo de titanio sin costura

-

Cambiador de calor del titanio

-

Tubería de la bobina del titanio

-

Hoja de la aleación del titanio

-

Sujetadores de titanio

-

Alambre de soldadura de titanio

-

Barra redonda del titanio

-

Piezas forjadas de titanio

-

Cobre revestido del titanio

-

Electrodo del titanio

-

Blanco de la farfulla del metal

-

Productos del circonio

-

Filtro poroso sinterizado

-

Alambre de Nitinol de la memoria de la forma

-

Productos de niobio

-

Productos del tungsteno

-

Productos del molibdeno

-

Productos de tántalo

-

Productos de equipos

-

productos de aluminio

-

productos de acero inoxidables

Componentes Forjados de Titanio de Precisión Soluciones de Ingeniería Personalizadas para Aplicaciones Aeroespaciales, Médicas e Industriales

| Place of Origin | China |

|---|---|

| Nombre de la marca | CSTI |

| Certificación | ISO9001 |

| Model Number | Grade 1, Grade 2 Ti ASTM B348 Dia 200-1000mm*l ≤300 |

| Minimum Order Quantity | 5 Kilograms |

| Precio | $12.50 - $27.50/ Kilogram |

| Packaging Details | 1.Plastic bags and foam paper as inside, Wooden case as outside; 2.packing according to your requirement. |

| Delivery Time | 15~25 work days |

| Payment Terms | T/T, L/C |

| Supply Ability | 30 Ton/Tons per Month |

| Resaltar | componentes aeroespaciales forjados de titanio de precisión,forjas de titanio personalizadas para aplicaciones médicas,soluciones de ingeniería industrial forjadas en titanio |

||

|---|---|---|---|

Descripción del Producto:

Las Forjas de Titanio representan un pináculo en la tecnología avanzada de trabajo de metales, ofreciendo una resistencia, durabilidad y resistencia a la corrosión excepcionales para una amplia gama de aplicaciones exigentes. Como componente crítico en industrias como la aeroespacial, automotriz, médica y marina, las Soluciones de Forja de Titanio brindan un rendimiento incomparable donde las relaciones de alta resistencia a peso y la confiabilidad son primordiales. Nuestras Forjas de Titanio de Alta Resistencia están diseñadas para cumplir con las especificaciones más estrictas, asegurando que cada producto ofrezca una calidad constante y propiedades mecánicas superiores.

Utilizando técnicas de forja de última generación, las Soluciones de Forja de Titanio permiten la transformación de palanquillas de titanio en bruto en formas complejas con una mayor integridad estructural. El proceso de forja alinea la estructura de grano del metal, mejorando significativamente la tenacidad y la resistencia a la fatiga en comparación con otros métodos de fabricación como el fundido o el mecanizado. Este refinamiento del grano da como resultado Forjas de Titanio que exhiben una resistencia excepcional, lo que las hace ideales para componentes críticos que soportan carga y que deben soportar estrés extremo y condiciones ambientales adversas.

Las Forjas de Titanio de Alta Resistencia son particularmente valoradas por su excepcional relación resistencia-peso, una ventaja clave en aplicaciones donde reducir el peso sin comprometer el rendimiento es esencial. Los fabricantes aeroespaciales confían en gran medida en estas forjas para producir piezas que contribuyen a aeronaves más ligeras y eficientes en combustible, manteniendo al mismo tiempo la seguridad y la durabilidad. De manera similar, en el sector automotriz, las forjas de titanio ayudan a mejorar el rendimiento del vehículo y la economía de combustible al reducir el peso total y mejorar la longevidad de los componentes.

Además de la resistencia mecánica, las Soluciones de Forja de Titanio ofrecen una excelente resistencia a la corrosión, lo que las hace adecuadas para su uso en entornos agresivos como plantas de procesamiento químico, embarcaciones marinas e implantes médicos. La biocompatibilidad inherente del titanio también hace que los componentes forjados sean ideales para instrumentos quirúrgicos y dispositivos protésicos, donde la confiabilidad y la seguridad son fundamentales. Nuestras Forjas de Titanio se someten a rigurosos controles de calidad y pruebas para garantizar que cumplan con los estándares internacionales, brindando confianza a los fabricantes y usuarios finales por igual.

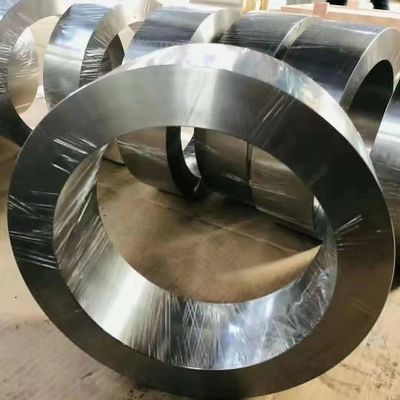

Nuestras completas Soluciones de Forja de Titanio abarcan una amplia gama de productos, incluyendo discos, anillos, barras y componentes de forma personalizada adaptados a los requisitos específicos de la aplicación. Empleamos modelado por computadora avanzado y equipos de forja de precisión para optimizar el diseño y el proceso de producción, lo que resulta en un desperdicio mínimo de material y una fabricación rentable. Este enfoque no solo apoya las prácticas sostenibles, sino que también permite tiempos de respuesta rápidos para proyectos urgentes.

La colaboración con nuestros clientes es fundamental para ofrecer Soluciones de Forja de Titanio que satisfagan con precisión sus necesidades. Desde la selección inicial de materiales y la consulta de diseño hasta la inspección final y la entrega, trabajamos en estrecha colaboración con los clientes para garantizar que cada forja supere las expectativas. Nuestra experiencia técnica y compromiso con la innovación impulsan la mejora continua en las técnicas de forja y el rendimiento de los materiales, manteniéndonos a la vanguardia de la industria de la forja de titanio.

Elegir Forjas de Titanio de Alta Resistencia significa invertir en componentes que combinan una construcción ligera con la máxima resistencia y durabilidad. Ya sea para motores aeroespaciales, dispositivos médicos, hardware marino o piezas automotrices de alto rendimiento, las forjas de titanio proporcionan una base confiable para un rendimiento superior del producto. Confíe en nuestras Soluciones de Forja de Titanio para ofrecer la calidad y consistencia necesarias para lograr la excelencia en sus procesos de fabricación.

En resumen, las Forjas de Titanio son una solución vital para las industrias que exigen materiales que ofrezcan alta resistencia, resistencia a la corrosión y propiedades de ligereza. Nuestras Soluciones de Forja de Titanio se destacan por sus procesos de fabricación avanzados, estrictos estándares de calidad y ofertas de productos a medida. Al seleccionar nuestras Forjas de Titanio de Alta Resistencia, los clientes se benefician de un rendimiento mejorado, una vida útil más larga y costos de producción optimizados, lo que las convierte en la opción preferida para aplicaciones críticas en todo el mundo.

Características:

- Forjas de Titanio de Alta Resistencia diseñadas para la durabilidad y el rendimiento

- Componentes Forjados de Titanio de precisión para diversas aplicaciones industriales

- Excelente resistencia a la corrosión que garantiza componentes forjados de titanio de larga duración

- Forjas de Titanio ligeras pero robustas adecuadas para los sectores aeroespacial y automotriz

- Forjas de Titanio personalizadas adaptadas para satisfacer los requisitos específicos del cliente

- Procesos de fabricación avanzados para producir Forjas de Titanio de Alta Resistencia de alta calidad

- Propiedades mecánicas superiores que proporcionan mayor resistencia y tenacidad

- Amplia gama de tamaños y formas disponibles para diversas necesidades de componentes forjados de titanio

Parámetros Técnicos:

| Nombre del Producto | Forjas Industriales de Titanio |

| Material | Aleaciones de Titanio Forjado |

| Resistencia | Forjas de Titanio de Alta Resistencia |

| Método de Forja | Forja en Matriz Cerrada, Forja en Matriz Abierta |

| Rango de Tamaño | Hasta 5000 mm de longitud |

| Rango de Peso | De 1 kg a 10.000 kg |

| Acabado de la Superficie | Mecanizado, Pulido, Granallado |

| Aplicaciones | Aeroespacial, Automotriz, Industria Química |

| Tratamiento Térmico | Recocido, Tratamiento de Solución, Envejecimiento |

| Certificación | ISO 9001, Estándares ASTM |

Aplicaciones:

Las Forjas de Titanio CSTI, disponibles en Grado 1 y Grado 2 Ti ASTM B348 con diámetros que van desde 200 mm hasta 1000 mm y longitudes de hasta 300 mm, están diseñadas para cumplir con los más altos estándares de calidad y rendimiento. Certificadas bajo ISO9001, estas forjas de titanio de precisión son ideales para una amplia gama de ocasiones y escenarios de aplicación donde la resistencia, la resistencia a la corrosión y las propiedades de ligereza son críticas. Con una cantidad mínima de pedido de solo 5 kilogramos y un rango de precios competitivo de $12.50 a $27.50 por kilogramo, CSTI ofrece soluciones de forja de titanio flexibles para satisfacer las necesidades industriales tanto a pequeña como a gran escala.

Estas forjas de metal de titanio se utilizan ampliamente en las industrias aeroespaciales, donde los componentes deben soportar condiciones extremas sin comprometer la durabilidad o el peso. Las forjas de titanio de precisión de CSTI garantizan un rendimiento fiable en las piezas de los motores de los aviones, los fuselajes y los componentes estructurales, ofreciendo una excelente resistencia a la fatiga y protección contra la corrosión. Además, las forjas de titanio de Grado 1 y Grado 2 desempeñan un papel fundamental en las aplicaciones marinas, donde la resistencia a la corrosión del agua de mar es primordial, lo que las hace adecuadas para la construcción naval, equipos submarinos y plantas de desalinización.

En el campo médico, las forjas de titanio de CSTI son buscadas para la fabricación de instrumentos quirúrgicos, implantes ortopédicos y dispositivos dentales debido a su biocompatibilidad y resistencia. La capacidad de personalizar el embalaje, incluyendo bolsas de plástico, papel de espuma y cajas de madera, asegura que las forjas de titanio lleguen en óptimas condiciones, listas para el mecanizado y montaje de precisión. Con una capacidad de suministro de 30 toneladas por mes y plazos de entrega que oscilan entre 15 y 25 días hábiles, CSTI garantiza el cumplimiento oportuno de los proyectos urgentes.

La industria automotriz también se beneficia de las soluciones de forja de titanio de CSTI, utilizando componentes de titanio ligeros para mejorar la eficiencia del combustible y el rendimiento en vehículos de alta gama y deportes de motor. Además, las plantas de procesamiento químico confían en las propiedades resistentes a la corrosión de las forjas de metal de titanio para tuberías, intercambiadores de calor y reactores, donde la durabilidad bajo la exposición a productos químicos agresivos es esencial.

En general, las forjas de titanio de CSTI ofrecen soluciones versátiles y de alta calidad en múltiples sectores, enfatizando la precisión, la fiabilidad y la personalización. Ya sea para aplicaciones aeroespaciales, médicas, marinas, automotrices o químicas, las soluciones de forja de titanio de CSTI se destacan como la opción preferida para ingenieros y fabricantes que requieren forjas de metal de titanio de primer nivel.

Soporte y Servicios:

Nuestro producto de Forjas de Titanio viene con un soporte técnico y servicios integrales para garantizar un rendimiento óptimo y la satisfacción del cliente. Proporcionamos documentación detallada del producto, incluyendo especificaciones, propiedades de los materiales y directrices de mecanizado para ayudar en el desarrollo de su aplicación. Nuestro experimentado equipo técnico está disponible para ofrecer asesoramiento experto sobre la selección de materiales, los procesos de forja y las técnicas de acabado adaptadas a los requisitos de su proyecto.

Ofrecemos servicios personalizados de pruebas y garantía de calidad para verificar las propiedades mecánicas y la precisión dimensional de las forjas de titanio. Además, nuestro soporte postventa incluye asistencia para la resolución de problemas, recomendaciones de mantenimiento y orientación sobre la manipulación y el almacenamiento para preservar la integridad de las forjas.

Para cualquier consulta técnica o necesidad de soporte relacionada con las Forjas de Titanio, nuestro equipo de soporte dedicado se compromete a proporcionar soluciones oportunas y eficaces para ayudarle a obtener los mejores resultados con nuestros productos.

Embalaje y Envío:

Nuestras Forjas de Titanio se embalan cuidadosamente para garantizar la máxima protección durante el transporte. Cada forja se envuelve en materiales protectores como película de plástico o acolchado de espuma para evitar daños en la superficie. Los productos envueltos se colocan de forma segura en cajas de madera resistentes o contenedores de metal, personalizados para adaptarse a las dimensiones y el peso de las forjas.

Para el envío, utilizamos transportistas fiables con experiencia en el manejo de bienes industriales pesados y de alto valor. Todos los paquetes están claramente etiquetados con instrucciones de manipulación y detalles del producto. También proporcionamos información de seguimiento para mantenerle actualizado durante todo el proceso de envío. Nuestros métodos de embalaje y envío garantizan que sus Forjas de Titanio lleguen de forma segura y en perfectas condiciones.

Preguntas Frecuentes:

P1: ¿Qué grados y especificaciones están disponibles para las Forjas de Titanio CSTI?

A1: Las Forjas de Titanio CSTI están disponibles en Grado 1 y Grado 2 según el estándar ASTM B348, con diámetros que van de 200 a 1000 mm y una longitud de hasta 300 mm.

P2: ¿Qué certificaciones tienen las Forjas de Titanio CSTI?

A2: Nuestras Forjas de Titanio están certificadas ISO9001, lo que garantiza procesos de fabricación de alta calidad y fiables.

P3: ¿Cuál es la cantidad mínima de pedido y el precio de las Forjas de Titanio CSTI?

A3: La cantidad mínima de pedido es de 5 kilogramos. El precio oscila entre $12.50 y $27.50 por kilogramo, dependiendo del grado y las especificaciones.

P4: ¿Qué condiciones de pago aceptan para la compra de Forjas de Titanio?

A4: Aceptamos pagos a través de T/T (Transferencia Telegráfica) y L/C (Carta de Crédito) para su comodidad.

P5: ¿Cuál es el tiempo de entrega y el método de embalaje típicos para las Forjas de Titanio CSTI?

A5: El tiempo de entrega suele ser de entre 15 y 25 días laborables. El embalaje incluye bolsas de plástico y papel de espuma en el interior, con una caja de madera en el exterior. También podemos embalar según sus requisitos específicos.