-

Accesorios de tubería de titanio

-

Tubo soldado con autógena titanio

-

Brida de tubo de titanio

-

Tubo de titanio sin costura

-

Cambiador de calor del titanio

-

Tubería de la bobina del titanio

-

Hoja de la aleación del titanio

-

Sujetadores de titanio

-

Alambre de soldadura de titanio

-

Barra redonda del titanio

-

Piezas forjadas de titanio

-

Cobre revestido del titanio

-

Electrodo del titanio

-

Blanco de la farfulla del metal

-

Productos del circonio

-

Filtro poroso sinterizado

-

Alambre de Nitinol de la memoria de la forma

-

Productos de niobio

-

Productos del tungsteno

-

Productos del molibdeno

-

Productos de tántalo

-

Productos de equipos

-

productos de aluminio

-

productos de acero inoxidables

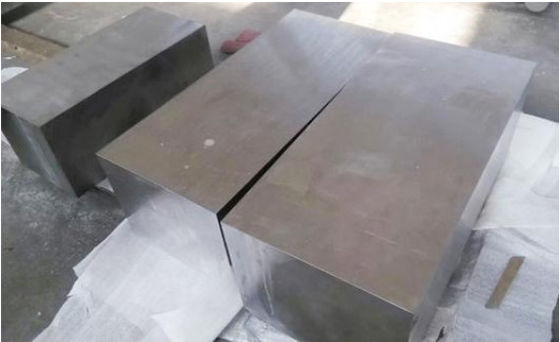

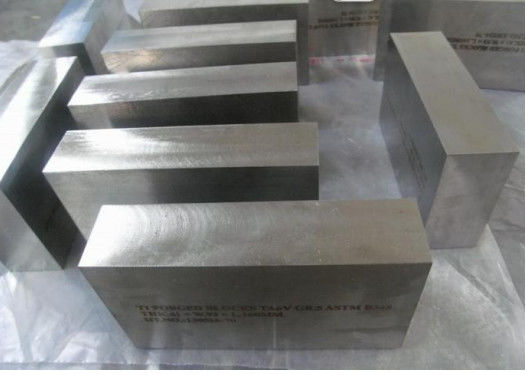

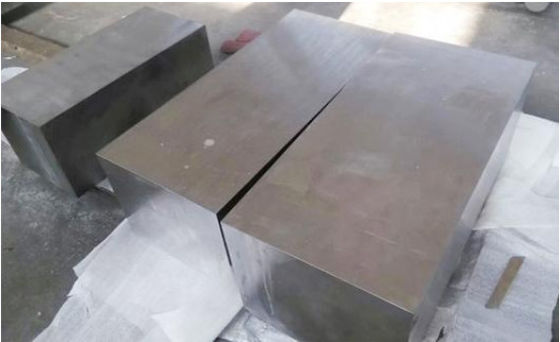

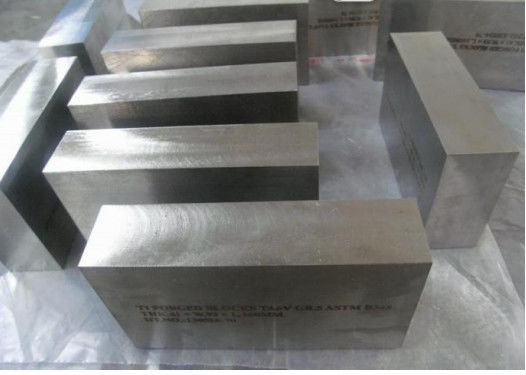

Componentes forjados de aleación de titanio de precisión diseñados para cumplir con estrictos estándares de la industria aeroespacial y médica

| Place of Origin | China |

|---|---|

| Nombre de la marca | CSTI |

| Certificación | ISO9001 |

| Model Number | Grade 1, Grade 2 Ti ASTM B348 Dia 200-1000mm*l ≤300 |

| Minimum Order Quantity | 5 Kilograms |

| Precio | $12.50 - $27.50/ Kilogram |

| Packaging Details | 1.Plastic bags and foam paper as inside, Wooden case as outside; 2.packing according to your requirement. |

| Delivery Time | 15~25 work days |

| Payment Terms | T/T, L/C |

| Supply Ability | 30 Ton/Tons per Month |

| Resaltar | Forjas de aleación de titanio de precisión,Componentes forjados de titanio para la industria aeroespacial,piezas de aleación de titanio de grado médico |

||

|---|---|---|---|

Descripción del producto:

Las forjas de titanio representan un proceso de fabricación avanzado que transforma el titanio crudo en componentes altamente duraderos y de ingeniería precisa.Estos elementos forjados de titanio personalizados son esenciales en varias industrias debido a su excepcional relación fuerza-peso.El proceso de forja consiste en moldear el titanio bajo alta presión.que perfecciona la estructura del grano y mejora el rendimiento general del material, por lo que es una opción ideal para aplicaciones críticas.

Una de las ventajas más significativas de las forjas de titanio es su ligereza combinada con una notable resistencia.Los componentes forjados de titanio ligeros son cada vez más solicitados en sectores como el aeroespacialLa reducción de peso contribuye a una mejor eficiencia de combustible, un mayor rendimiento, una mayor eficiencia de la energía y una mayor eficiencia de la energía.y emisiones más bajas, alineándose con las demandas de la industria moderna de soluciones sostenibles y de alto rendimiento.

En aplicaciones marinas, los materiales de forja de titanio marino se destacan debido a su excepcional resistencia a la corrosión del agua de mar y a la contaminación biológica.La capa de óxido natural de titanio proporciona una protección excepcional contra los ambientes marinos hostilesEsto hace que las forjas marinas de titanio sean la opción preferida para la fabricación de componentes como ejes de hélice, cuerpos de válvulas, componentes de bombas,y partes estructurales submarinasEstos elementos garantizan una larga vida útil y reducen los costes de mantenimiento, que son vitales para las operaciones marítimas.

La versatilidad de los forjados de titanio se extiende a su capacidad de ser personalizados de acuerdo con los requisitos de diseño específicos.y propiedades mecánicas para satisfacer los estrictos estándares de la industria y las necesidades únicas del proyectoLas técnicas de forja avanzadas, incluidas las de forja cerrada y abierta, permiten a los fabricantes producir geometrías complejas con una excelente precisión dimensional y un mínimo desperdicio de material.Esta capacidad de personalización permite a los ingenieros optimizar el rendimiento de los componentes manteniendo la eficiencia de costos.

Por otra parte, el proceso de fabricación de las forjas de titanio requiere rigurosas medidas de control de calidad para garantizar la consistencia y fiabilidad.como la inspección por ultrasonido y el análisis por rayos XEste nivel de control garantiza que cada componente de titanio forjado cumple o excede las especificaciones requeridas.Infundir confianza en los usuarios finales en todas las industrias exigentes.

Desde las palas de las turbinas aeroespaciales hasta los implantes médicos y los equipos deportivos de alto rendimiento, la gama de aplicaciones de las forjas de titanio es vasta.La biocompatibilidad inherente del titanio también abre oportunidades en el campo médico, donde se utilizan elementos forjados de titanio personalizados para crear implantes e instrumentos quirúrgicos que requieren resistencia y compatibilidad con el cuerpo humano.

Además de las ventajas mecánicas, las forjas de titanio contribuyen a la sostenibilidad ambiental.La longevidad y la durabilidad de los componentes forjados de titanio ligero reducen la frecuencia de reemplazos y reparacionesAdemás, la reciclabilidad del titanio se alinea con las prácticas de fabricación ecológica.haciendo que sea una elección responsable de material para industrias con visión de futuro.

En resumen, las forjas de titanio ofrecen una combinación incomparable de resistencia, rendimiento ligero, resistencia a la corrosión y flexibilidad de personalización.Ya sea utilizado como materiales de forja de titanio marino en ambientes oceánicos exigentes o como elementos forjados de titanio personalizados en aplicaciones aeroespaciales y médicasLos avances en la tecnología de forja continúan ampliando las posibilidades de los componentes de titanio.reforzar su posición como material crítico para las soluciones modernas de ingeniería.

Características:

- Componentes forjados de aleación de titanio de alta calidad

- Productos forjados de titanio de precisión con una excelente precisión dimensional

- Partes metálicas forjadas de titanio duraderas y resistentes a la corrosión

- Forjas de titanio ligeras pero resistentes, adecuadas para diversas industrias

- Diseños personalizables para satisfacer los requisitos específicos de las aplicaciones

- Mejora de las propiedades mecánicas mediante técnicas avanzadas de forja

- Ideal para aplicaciones aeroespaciales, médicas, automotrices e industriales

- Control de calidad constante que garantice un rendimiento fiable

- Procesos de fabricación respetuosos con el medio ambiente

Parámetros técnicos:

| Nombre del producto | Partes de titanio forjadas |

| El material | aleación de titanio (grados 2, 5, 7, 9) |

| Peso | Componentes forjados de titanio ligeros |

| Proceso de fabricación | Forja cerrada a presión |

| Las dimensiones | Personalizable según los requisitos de piezas forjadas de titanio industrial |

| Finalización de la superficie | Mecanizado, pulido o disparado |

| Propiedades mecánicas | Alta relación fuerza/peso, excelente resistencia a la corrosión |

| Aplicaciones | Piezas forjadas de titanio para la industria aeroespacial, automotriz, naval, médica e industrial |

| Tratamiento térmico | Anulación, tratamiento con solución, envejecimiento |

| Certificación | Conforme a las normas ISO 9001 y ASTM |

Aplicaciones:

Las forjas de titanio CSTI, disponibles en el grado 1 y el grado 2 Ti ASTM B348 con diámetros de 200 mm a 1000 mm y longitudes de hasta 300 mm,están diseñados para satisfacer las exigentes necesidades de diversas aplicaciones industrialesCertificadas bajo ISO9001 y originarias de China, estas piezas forjadas de titanio industrial son reconocidas por su excepcional calidad y fiabilidad.Su alta resistencia y propiedades de peso ligero los hacen ideales para su uso en sectores donde la durabilidad y la reducción de peso son factores críticos.

Estas forjas de titanio de alta resistencia se utilizan ampliamente en componentes aeroespaciales, donde el rendimiento en condiciones extremas es esencial. Their excellent corrosion resistance and strength-to-weight ratio ensure that aircraft parts made from CSTI titanium forgings can withstand harsh environments while contributing to overall fuel efficiencyDe manera similar, en la industria marítima, estos componentes ligeros forjados en titanio se emplean en la construcción naval y en estructuras marinas.proporcionando una resistencia superior a la corrosión del agua de mar y al estrés mecánico.

En las industrias de procesamiento químico y generación de energía, las piezas forjadas de titanio de CSTI se utilizan para fabricar componentes críticos como intercambiadores de calor, válvulas y bombas.Su capacidad para resistir la degradación química y mantener la integridad estructural a altas temperaturas garantiza la seguridad operativa y la longevidadAdemás, estas forjas son una solución perfecta para la fabricación de equipos médicos, donde la biocompatibilidad y la resistencia son primordiales.

Con una cantidad mínima de pedido de sólo 5 kilogramos y precios competitivos entre $ 12.50 y $ 27.50 por kilogramo, CSTI ofrece soluciones rentables tanto para proyectos a pequeña como para proyectos a gran escala.Las condiciones de pago incluyen T/T y L/C proporcionan arreglos financieros flexibles para satisfacer las diversas necesidades de los clientesLa capacidad de suministro de 30 toneladas por mes garantiza la disponibilidad oportuna, con tiempos de entrega entre 15 y 25 días hábiles, lo que convierte a CSTI en un socio confiable para demandas de producción urgentes y continuas.

El embalaje se maneja cuidadosamente para garantizar la seguridad del producto, con bolsas de plástico y papel espuma utilizados en el interior y estuches de madera resistentes en el exterior.garantizar que cada envío llegue en condiciones óptimasYa sea para aplicaciones aeroespaciales, marinas, químicas o médicas, las piezas forjadas de titanio industrial de CSTI ofrecen un rendimiento, una resistencia y una resistencia inigualables.y ventajas ligeras que impulsan la innovación en todas las industrias.

Apoyo y servicios:

Nuestro producto de Forja de Titanio está respaldado por un amplio soporte técnico y servicios para garantizar un rendimiento óptimo y la satisfacción del cliente.optimización del diseñoNuestro equipo asiste con los procedimientos de garantía de calidad, incluyendo informes de inspección detallados y documentación de certificación.Además, ofrecemos orientación sobre el manejo adecuado, mecanizado y técnicas de acabado para maximizar la durabilidad y funcionalidad de las forjas de titanio.Nuestro apoyo se extiende a la solución de problemas y resolución de cualquier problema técnicoEstamos comprometidos a ofrecer soluciones de forja de titanio confiables y de alta calidad con servicio dedicado durante todo el ciclo de vida del producto.

Embalaje y envío:

Nuestras forjas de titanio están cuidadosamente empaquetadas para garantizar la máxima protección durante el transporte.Cada forja se envuelve en materiales resistentes a la corrosión y se coloca en cajas de madera o en contenedores de acero resistentesTodos los envases cumplen con las normas internacionales de envío para evitar daños y contaminación.

Para el transporte marítimo, ofrecemos opciones flexibles incluyendo el transporte aéreo, marítimo y terrestre.Nuestro equipo de logística se coordina estrechamente con transportistas confiables para garantizar la entrega oportuna y segura a su destino especificadoSe proporciona información de seguimiento para todos los envíos para mantenerlo informado durante todo el proceso de entrega.

Preguntas frecuentes:

P1: ¿Qué grados de forjas de titanio ofrecen?

R1: Ofrecemos forjas de titanio de grado 1 y grado 2, que cumplen con las normas ASTM B348.

P2: ¿Cuál es el rango de diámetro y la longitud disponibles para sus forjas de titanio?

R2: Nuestras forjadoras de titanio están disponibles en diámetros que van desde 200 mm hasta 1000 mm, con longitudes de hasta 300 mm.

P3: ¿Qué certificaciones tienen sus forjadoras de titanio?

A3: Nuestras forjadoras de titanio están certificadas ISO9001, lo que garantiza procesos de fabricación de alta calidad y confiables.

P4: ¿Cuál es su cantidad mínima de pedido y detalles de precios?

R4: La cantidad mínima de pedido es de 5 kilogramos. Los precios oscilan entre 12,50 y 27,50 dólares por kilogramo, dependiendo de las especificaciones y el tamaño del pedido.

P5: ¿Cuáles son sus términos de pago y tiempo de entrega para Forja de Titanio?

A5: Aceptamos métodos de pago T/T y L/C. Nuestro tiempo de entrega típico oscila entre 15 y 25 días hábiles después de la confirmación del pedido.

P6: ¿Cómo empaquetas las forjas de titanio para su envío?

A6: Los forjadores de titanio están empaquetados con bolsas de plástico y papel de espuma en el interior, y una caja de madera en el exterior. También podemos personalizar el embalaje de acuerdo con sus requisitos.

P7: ¿Cuál es su capacidad de suministro mensual para Forjadoras de Titanio?

A7: Tenemos una capacidad de suministro de 30 toneladas por mes para satisfacer su demanda.