-

Accesorios de tubería de titanio

-

Tubo soldado con autógena titanio

-

Brida de tubo de titanio

-

Tubo de titanio sin costura

-

Cambiador de calor del titanio

-

Tubería de la bobina del titanio

-

Hoja de la aleación del titanio

-

Sujetadores de titanio

-

Alambre de soldadura de titanio

-

Barra redonda del titanio

-

Piezas forjadas de titanio

-

Cobre revestido del titanio

-

Electrodo del titanio

-

Blanco de la farfulla del metal

-

Productos del circonio

-

Filtro poroso sinterizado

-

Alambre de Nitinol de la memoria de la forma

-

Productos de niobio

-

Productos del tungsteno

-

Productos del molibdeno

-

Productos de tántalo

-

Productos de equipos

-

productos de aluminio

-

productos de acero inoxidables

Sintered Plate Inconel600 Titanium SS 316L For Filtration And Separation

| Lugar de origen | PORCELANA |

|---|---|

| Nombre de la marca | CSTY |

| Certificación | GB/T19001-2016/ISO9001:2015 |

| Número de modelo | SS 316L |

| Cantidad de orden mínima | 10 kgs |

| Precio | $80.00 - $110.00/ Piece |

| Detalles de empaquetado | Película y caja de madera, cartón de embalaje puede ser de acuerdo con los requisitos del cliente. |

| Tiempo de entrega | 15 ~ 20 días de trabajo |

| Condiciones de pago | L/C, T/T, Western Union, Moneygram, PayPal |

| Capacidad de la fuente | En el caso de los productos que no estén sujetos a restricción, el valor de la restricción será igua |

Éntreme en contacto con gratis las muestras y los vales.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si usted tiene alguna preocupación, proporcionamos ayuda en línea de 24 horas.

x| Precisión de la filtración | 0.1um | Resistencia a la abrasión | Alto |

|---|---|---|---|

| característica | Utilizado en entornos altamente corrosivos | Área de filtración | 0.3-1.0m2 |

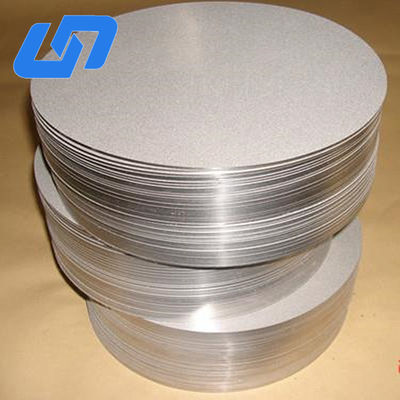

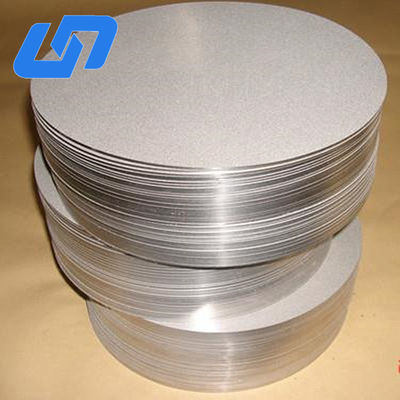

| Especificación | 0.5um, 2um, 5um, 10um, | Diámetro | 50 a 1000 mm |

| Material | Titanio, SS 316L, Inconel600, etc. | Servicio de la muestra | Proporcione la muestra para probar |

| Tipo | metal, disco de filtro SS | Estándar | ISO9000 |

| Presión de trabajo | 2-3Mpa | Embalaje | Paquete de exportación estándar |

| Vida útil | 2-5 años | Presión máxima | 2.0Mpa |

| Dimensión | Personalizado | ||

| Resaltar | Placa filtrante porosa sinterizada de Inconel 600,Placa de filtración sinterizada de titanio,Placa de separación sinterizada de SS 316L |

||

Introduction

Compared with traditional filtration materials such as paper, cotton, PP, PE, PES, and PTFE, metal powder sintered porous materials offer superior performance. They provide excellent permeability, precise pore size control, stable shape, high filtration accuracy, wear resistance, good mechanical strength, and excellent heat conduction and dissipation.

Moreover, sintered metal materials can withstand high temperatures, maintain their shape under stress, and be cleaned and reused multiple times, making them a durable and cost-effective filtration solution.

Specifications

| Product Name | Sintered Plate |

|---|---|

| Material | Pure Titanium / SS316L / Bronze / Inconel 600 |

| Size | OD 20–80 mm × WT 2.5–3.0 mm × L 10–1200 mm |

| Filter Accuracy | 0.5–80 µm |

| Connection | Customized according to customer requirements |

| Applications | Sparging, Separation and Filtration, Carbonation, Liquid Filtration, etc. |

Technical Parameters

| Filter Accuracy (µm) | Porosity (%) | Permeability (m³/m²·h·kPa) | Compression Strength (MPa) | Temperature Tolerance (°C) | Max Working Pressure (MPa) |

|---|---|---|---|---|---|

| 0.5–50 | 20–50 | 3–800 | 2–3 | 250 | 0.6 |

Applications

The sintered plate is widely used in industries including electronics, water treatment, food and beverage, biotechnology, chemicals, petrochemicals, metallurgy, and gas purification. It represents a new generation of filtration materials with broad development potential.

Typical applications include:

-

Sparging

-

Separation and Filtration

-

Carbonation

-

Liquid Filtration

-

Catalyst Recovery

-

Steam Filtration

-

Slurry Oil Filtration

-

Flame Arrestors

-

Sound Silencing

-

Fluid Distribution and Control

-

Semiconductor Manufacturing

-

Fuel Cell Stacks

-

Coating Electrodes

-

Damping and Shock Absorption

-

Heat Exchange

-

Bio-Implants

Properties

-

Uniform pore size and stable pore structure with high separation efficiency

-

High porosity, low filtration resistance, and excellent permeability

-

Outstanding chemical stability and resistance to acids, alkalis, and oxidation

-

Morphological stability—no particle shedding; compliant with food hygiene and pharmaceutical GMP standards

-

Strong mechanical properties, low differential pressure, and large flow capacity

-

Excellent anti-microbial characteristics, non-reactive with microorganisms

-

Easy online regeneration, backwashing, and long service life

-

Excellent biocompatibility for use in biological, food, pharmaceutical, and medical applications

-

Effective electromagnetic shielding performance

-

Strong damping and shock resistance