-

Accesorios de tubería de titanio

-

Tubo soldado con autógena titanio

-

Brida de tubo de titanio

-

Tubo de titanio sin costura

-

Cambiador de calor del titanio

-

Tubería de la bobina del titanio

-

Hoja de la aleación del titanio

-

Sujetadores de titanio

-

Alambre de soldadura de titanio

-

Barra redonda del titanio

-

Piezas forjadas de titanio

-

Cobre revestido del titanio

-

Electrodo del titanio

-

Blanco de la farfulla del metal

-

Productos del circonio

-

Filtro poroso sinterizado

-

Alambre de Nitinol de la memoria de la forma

-

Productos de niobio

-

Productos del tungsteno

-

Productos del molibdeno

-

Productos de tántalo

-

Productos de equipos

-

productos de aluminio

-

productos de acero inoxidables

RO4200-1 RO4210-2 Tubo capilar de niobio para acelerar y aumentar la presión

| Lugar de origen | PORCELANA |

|---|---|

| Nombre de la marca | Changsheng |

| Certificación | ISO 9001;2015 |

| Número de modelo | Las demás partidas de los componentes de las máquinas |

| Cantidad de orden mínima | 100pcs |

| Precio | USD58.00/pc |

| Detalles de empaquetado | Paquete de exportación Stardard |

| Tiempo de entrega | 15-30 días |

| Condiciones de pago | L/C, T/T, Western Union, Moneygram, PayPal |

| Capacidad de la fuente | 500 kg/mes |

Éntreme en contacto con gratis las muestras y los vales.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si usted tiene alguna preocupación, proporcionamos ayuda en línea de 24 horas.

x| Producto | Tubo de niobio | Composición química | Nb>=99,95% |

|---|---|---|---|

| Método | El horno de haz de electrones fundido | Dimensiones | ¢3 ~ ¢120 mm |

| Tamaño | Personalizado | Pureza | 99.9%(3n) |

| Estándar | Las demás partidas | Condiciones | recocido al vacío |

| Estándar de material | Las demás partidas de los productos | Técnica | Sinterizado, Forjado, Mecanizado |

| Tecnología | Máquinas de fresado CNC | Calor de fusión | 26.4 KJ/mol |

| Temperatura de evaporación | 2350°C (menos de 10-4Torr) | Fuerza de rendimiento | 73MPa |

| Año de descubrimiento | 1801 | Lugar original | PORCELANA |

| Capacidad de calor específica | 0.265 J/g·K | Calificación | RO4200 |

| Número atómico | 41 | Condición superficial | limpio o negro |

| Tratamiento | Rodando en frío | Norma de fabricación | Las demás partidas de los componentes de las placas de ensayo |

| Punto de fusión | 2.468 ° C | Especificación | Personalizado |

| Forma | Tubo | Conductividad eléctrica | 0.0693 10^6/cm |

| Densidad | 8.57 g/cm³ | Palabra clave | tubos capilares de Niobium |

| Resaltar | de niobio para el estrangulamiento de tubos capilares,tubo de aumento de presión de niobio,productos de niobio con garantía |

||

Introducción

El tubo de niobio es un tipo de tubería utilizada para transportar y transferir materiales en condiciones especiales, como alta temperatura y alta presión, que se utiliza ampliamente en la industria nuclear, aeroespacial, naval, química y electrónica. Debido a la excelente resistencia a la corrosión y la estabilidad a altas temperaturas del niobio, los tubos de niobio tienen fuertes características de compresión, tracción, fatiga y resistencia al calor, por lo que se utilizan ampliamente en varios campos de alta gama.

Composición química:

| Química (%) | ||||||||||||

| Grado | Componente principal | Otras impurezas (≤) | ||||||||||

| Nb | Fe | Si | Ni | W | Mo | Ti | Ta | O | C | H | N | |

| Nb1 | Resto | 0.004 | 0.004 | 0.002 | 0.005 | 0.005 | 0.002 | 0.05 | 0.015 | 0.004 | 0.0015 | 0.003 |

| Nb2 | Resto | 0.01 | 0.01 | 0.005 | 0.02 | 0.01 | 0.004 | 0.07 | 0.02 | 0.01 | 0.0015 | 0.008 |

Tratamiento de la superficie

El tratamiento de la superficie del tubo de niobio generalmente incluye pulido mecánico, pulido electrolítico, decapado y granallado. El pulido mecánico y el pulido electrolítico pueden mejorar el acabado superficial y la planitud del tubo de niobio, y mejorar la resistencia a la corrosión del tubo de niobio. El decapado y el granallado pueden eliminar impurezas como aceite y óxido en la superficie del tubo de niobio para garantizar la limpieza y la planitud de la superficie del tubo de niobio.

Aplicaciónde niobio

1, aleación de alta temperatura;

2, aleación base de niobio;

3, aplicaciones de acero;

4. Porcelana eléctrica;

5. Dinero;

6. Campo médico;

7. Campo médico;

8. Industria aeroespacial

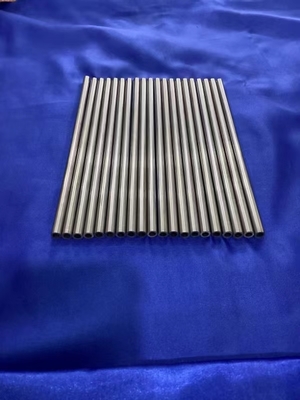

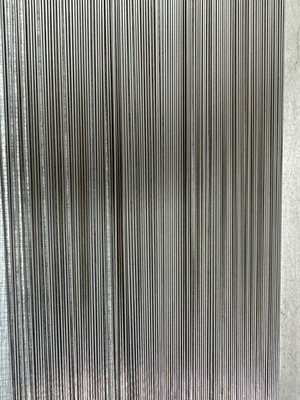

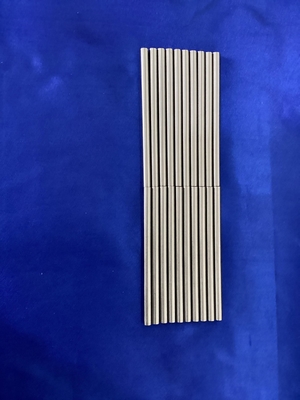

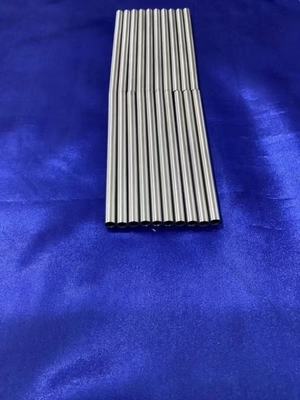

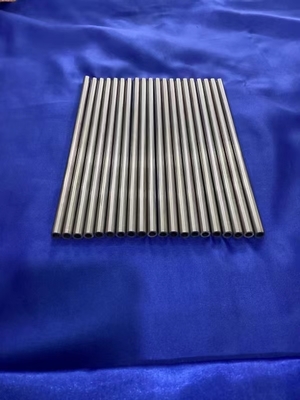

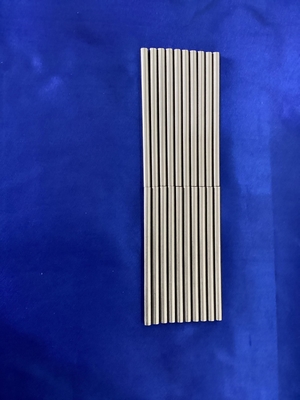

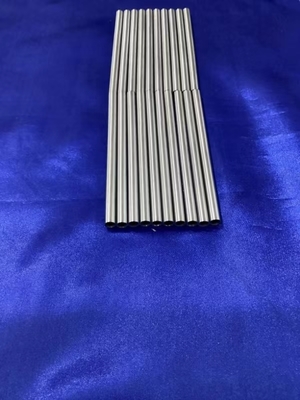

Foto del producto

![]()

FRQ

Certificado CE SAA ROHS Comercial Luces de inundación LED impermeables IP65 para exteriores 20W 30W 50W 100W 200W 12V

P1. ¿Puedo tener un pedido de muestra para la luz LED?

R: Sí, damos la bienvenida a pedidos de muestra para probar y verificar la calidad. Se aceptan muestras mixtas.

P2. ¿Qué pasa con el tiempo de entrega?

R: 3-5 días para la preparación de la muestra, 8-10 días hábiles para la producción en masa.

P3. ¿Tiene algún límite de MOQ para pedidos de luces LED?

R: MOQ bajo, 1 pieza para la verificación de la muestra está disponible.

P4. ¿Cómo se envían los productos y cuánto tiempo tarda en llegar?

R: Envíe por DHL, UPS, FedEx o TNT. Tarda entre 3 y 5 días en llegar. El envío aéreo y marítimo también es opcional.

P5. ¿Cómo proceder con un pedido de luces LED?

R: En primer lugar, háganos saber sus requisitos o aplicación.

En segundo lugar, cotizamos de acuerdo con sus requisitos o nuestras sugerencias.

En tercer lugar, el cliente confirma las muestras y realiza un depósito para el pedido formal.

En cuarto lugar, organizamos la producción.

P6. ¿Está bien imprimir mi logotipo en el producto de luz LED?

R: Sí. Infórmenos formalmente antes de nuestra producción.

P7: ¿Ofrecen garantía para los productos?

R: Sí, ofrecemos una garantía de 5 años para nuestros productos.

P8: ¿Cómo lidiar con los defectuosos?

R: En primer lugar, nuestros productos se producen en un estricto sistema de control de calidad, y la tasa de defectos será inferior al 0,2%.

En segundo lugar, durante el período de garantía, enviaremos nuevas luces con un nuevo pedido para una pequeña cantidad. Para los productos defectuosos por lotes, los repararemos y se los reenviaremos, o podemos discutir la solución, incluida la retirada, de acuerdo con la situación real.